Choosing the Perfect O-Ring: A Survival Guide for Engineers

Choosing the Perfect O-Ring: A Survival Guide for Engineers

Introduction: The Cost of a Poor Seal

A failed O-ring can shut down a factory, delay a space launch, or contaminate a vaccine batch. Selecting the right O-ring isn’t just about specs—it’s about risk management. This guide decodes the art and science behind O-ring selection.Material Matters: The Five Most Common Elastomers

Nitrile (NBR): Affordable, oil-resistant, and perfect for automotive fuel systems.

Limitation: Poor performance in ozone or extreme heat.

Viton® (FKM): Handles temperatures up to 400°F and aggressive chemicals. Ideal for aerospace.

Trade-off: Higher cost and less flexibility at low temps.

Silicone (VMQ): Non-toxic and heat-resistant (up to 500°F), used in medical and food-grade applications.

Weakness: Low tear strength.

EPDM: Excellent for water, steam, and UV resistance. Common in plumbing and solar panels.

Avoid: Petroleum-based fluids.

PTFE (Teflon®): Nearly chemically inert, perfect for semiconductor manufacturing.

Challenge: Requires precise compression to seal.

The Four Pillars of O-Ring Selection

Temperature Range

Example: A car engine O-ring faces -40°F (cold starts) to 300°F (operating heat). Silicone or FKM is ideal.

Chemical Compatibility

Tip: Use compatibility charts—e.g., EPDM fails with gasoline, while NBR thrives.

Pressure Dynamics

High-pressure hydraulics need reinforced O-rings with backup rings to prevent extrusion.

Application Motion

Static seals (e.g., pipe fittings) vs. dynamic seals (e.g., piston shafts). Dynamic apps require abrasion-resistant materials.

Sizing Secrets: Avoiding the “Close Enough” Trap

Measure Twice: An O-ring’s inner diameter (ID), cross-section (CS), and gland dimensions must align. Even a 0.1mm error can cause leaks.

Compression Basics: Aim for 15–30% compression. Too little? Leaks. Too much? Permanent deformation.

AS568 Standards: The aerospace industry’s sizing code ensures global consistency.

Case Study: When the Wrong Material Sank a Submarine

In 2018, a naval submarine’s EPDM O-rings degraded after exposure to diesel fuel, causing a hazardous leak. Switching to FKM resolved the issue—a lesson in chemical compatibility.Installation & Maintenance: Maximizing Lifespan

Lubrication: Use silicone grease to prevent twisting during installation.

Inspection: Check for nicks, flat spots, or swelling during maintenance.

Storage: Keep O-rings in cool, dark conditions to avoid ozone cracking.

The Future: Digital Tools Revolutionizing Selection

AI-Powered Databases: Apps like Seal Selector Pro cross-reference materials, temps, and chemicals to recommend the best O-ring.

Augmented Reality (AR): Technicians use AR glasses to visualize gland dimensions in real-time.

YIWU GREAT SEAL CAN SUPPLY YOU HIGH QUALITY O RING PRODUCTS AS YOUR TECHNICAL DATA,OEM AND ODM IS AVALIABLE

Hot Products

-

View More

View More

-

View More

View More

Magnetic Abs OEM Bearing Seals China Manufacturer

-

View More

View More

Automobile Brake Disc Wheel Bearing Seals China Supplier

-

View More

View More

EPDM rubber o-ring seal different size factory China manufacturer

-

View More

View More

Automotive Oil Filter Rubber Check Valve

-

View More

View More

HNBR O Ring Seal OEM Manufacturer China

-

View More

View More

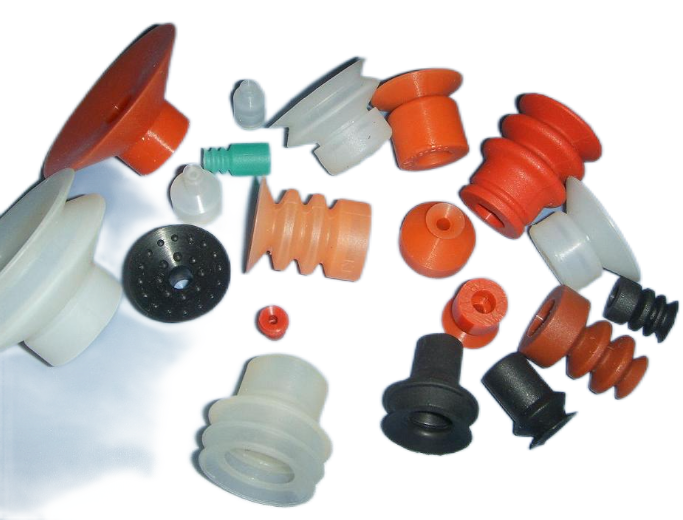

Rubber High Pressure Suction For Electronic Hand OEM China Factory

-

View More

View More

John Deere Tractor Cassette oil seal RWDR Manufacturer

-

View More

View More

High Pressure TCN Oil Seal for Excavator

-

View More

View More

Trailer Grease shaft rubber lip oil seal TB 11174

-

View More

View More

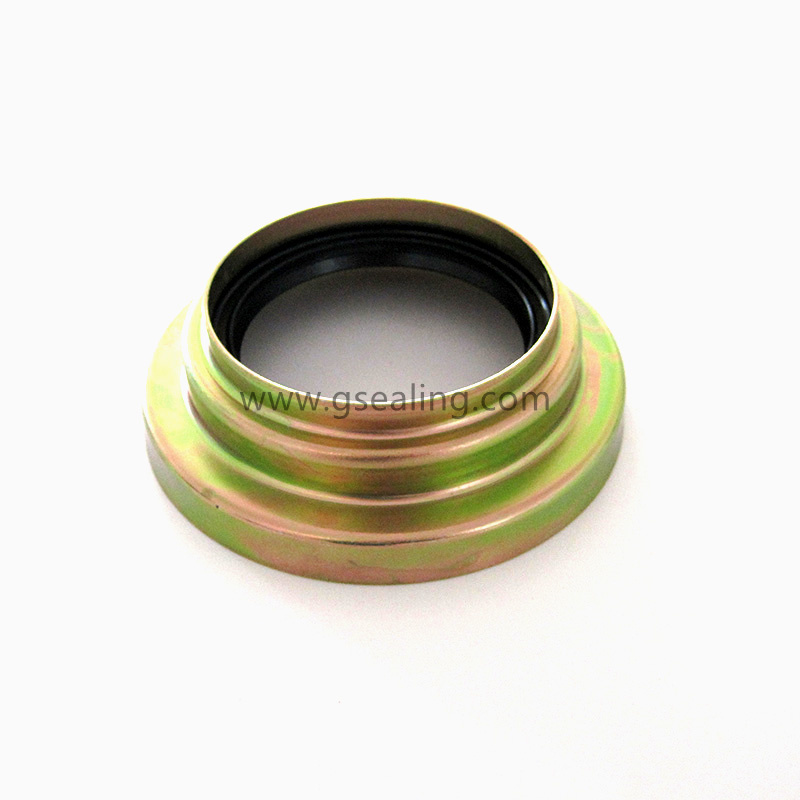

Ford New Holland Tractor Half Shaft Seal Retainer Assembly China Manufacturer

-

View More

View More

Irrigation Valley Valmont Gearbox Oil Seal China Supplier

-

View More

View More

High Quality Agriculture Machinery Rotation Oil Seal Kits

-

View More

View More

John Deer Grease Drive Shaft Oil Seal China Supplier

-

View More

View More

Tractor shaft combine oil seal