How to Choose the right fuel filter rubber O-ring seals

Choosing the right fuel filter rubber O-ring seals involves considering several critical factors to ensure a reliable and safe seal. Here's a structured approach:

1. Material Compatibility

- Fuel Type:** Select a material resistant to the specific fuel (gasoline, diesel, ethanol blends like E85).

- Nitrile (NBR):** Cost-effective, good for standard fuels and oils. Avoid with high ethanol content.

- Viton (FKM):** Superior for high temperatures, aggressive chemicals, and ethanol blends.

- Silicone & EPDM:** Avoid; poor fuel resistance (EPDM resells UV/ozone but not fuels).

2. Temperature Range

- Ensure the material withstands operational temperatures (e.g., engine heat and cold starts). Viton excels in high temps (-20°C to 200°C), while Nitrile suits moderate ranges (-40°C to 120°C).

3. Chemical Resistance

- Check additives (e.g., ethanol, detergents). Viton resists ethanol better than Nitrile, crucial for E85.

4. Size & Dimensions

- Measure **Inner Diameter (ID)** and **Cross-Section (CS)** precisely. Use OEM specs or calipers on the old O-ring. Metric (AS568) or imperial standards apply.

5. Hardness (Shore A Durometer)

- Typically 70-90 Shore A. Balance flexibility and compression resistance. Higher hardness for high-pressure systems.

6. Pressure Rating

- Ensure the O-ring material can handle system pressure without extrusion. Viton performs better under higher pressures.

7. Certifications & Standards

- Look for SAE, ISO, or OEM certifications (e.g., SAE J2643 for fuel systems).

8. Manufacturer Specifications

- Follow OEM recommendations. Cross-reference part numbers if replacing.

9. Cost vs. Performance

- Nitrile is economical for standard use; Viton offers longevity in harsh conditions.

10. Environmental Factors

- Consider abrasion, UV exposure, and compression set resistance. Viton has low compression set, ideal for long-term seals.

11. Shelf Life & Storage

- Nitrile degrades faster (~15 years shelf life) vs. Viton (~20 years). Store in cool, dry conditions.

12. Application Type

- Static seals (common in fuel filters) vs. dynamic. Most fuel filters use static seals, simplifying material choice.

Summary Checklist:

1. Confirm fuel type and chemical additives.

2. Verify temperature and pressure requirements.

3. Measure ID/CS or check OEM specs.

4. Choose material (Viton for ethanol/high temp; Nitrile for standard fuels).

5. Ensure hardness (70-90 Shore A) matches pressure needs.

6. Check certifications and manufacturer guidelines.

7. Balance cost with expected lifespan.

8. Verify availability from suppliers.

By systematically evaluating these factors, you can select an O-ring that ensures a leak-free, durable seal for your fuel filter application.

YIWU GREAT SEAL RUBBER PRODUCTS SPECIALIZED IN DIFFERENT FUEL INJECTOR O-RINGS AND SEALS MEET YOUR REQUIREMENTS. CONTACT US : sale@gsealing.com

NEXT:No more!

Hot Products

-

View More

View More

-

View More

View More

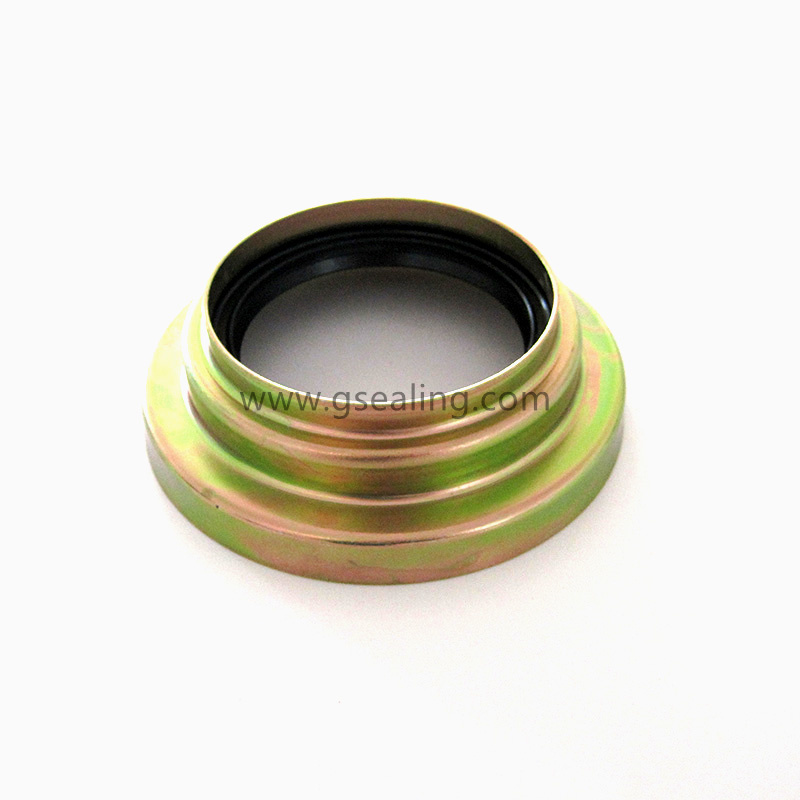

Magnetic Abs OEM Bearing Seals China Manufacturer

-

View More

View More

Automobile Brake Disc Wheel Bearing Seals China Supplier

-

View More

View More

EPDM rubber o-ring seal different size factory China manufacturer

-

View More

View More

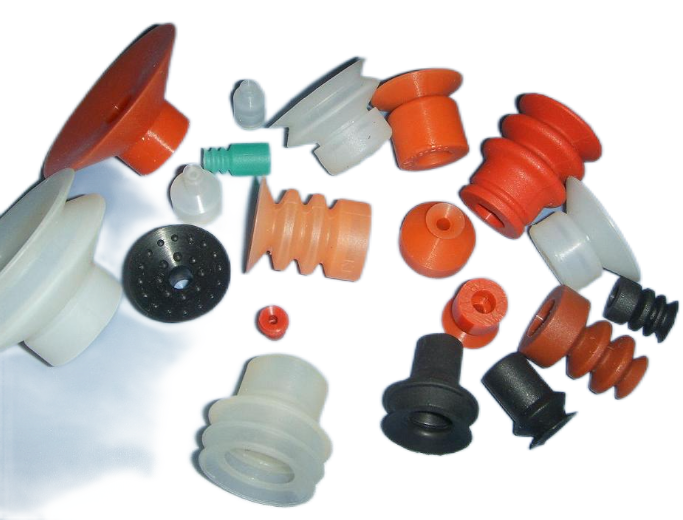

Automotive Oil Filter Rubber Check Valve

-

View More

View More

HNBR O Ring Seal OEM Manufacturer China

-

View More

View More

Rubber High Pressure Suction For Electronic Hand OEM China Factory

-

View More

View More

John Deere Tractor Cassette oil seal RWDR Manufacturer

-

View More

View More

High Pressure TCN Oil Seal for Excavator

-

View More

View More

Trailer Grease shaft rubber lip oil seal TB 11174

-

View More

View More

Ford New Holland Tractor Half Shaft Seal Retainer Assembly China Manufacturer

-

View More

View More

Irrigation Valley Valmont Gearbox Oil Seal China Supplier

-

View More

View More

High Quality Agriculture Machinery Rotation Oil Seal Kits

-

View More

View More

John Deer Grease Drive Shaft Oil Seal China Supplier

-

View More

View More

Tractor shaft combine oil seal