O-Rings: The Tiny Giants of Engineering That Keep the World Sealed

O-Rings: The Tiny Giants of Engineering That Keep the World Sealed

Introduction: The Invisible Guardians

Imagine a world where rockets leak fuel, car engines spew oil, and your coffee maker drips water onto the counter. This chaos is prevented by a simple yet extraordinary component: the O-ring. These unassuming circular seals are the unsung heroes of engineering, quietly ensuring everything from space missions to kitchen appliances function flawlessly.

A Brief History: From Obscurity to Ubiquity

Invention: The modern O-ring was patented in 1936 by Danish-American machinist Niels Christensen. Originally designed for hydraulic brake systems in cars, its versatility soon made it indispensable.

Space Age Breakthrough: O-rings gained fame (and infamy) during NASA’s Space Shuttle program. The 1986 Challenger disaster, caused by a failed O-ring in cold temperatures, underscored their critical role—and the importance of material science.

Today: Over 10 billion O-rings are produced annually, used in industries ranging from pharmaceuticals to deep-sea exploration.

How O-Rings Work: The Science of Squish

O-rings rely on elastic deformation. When compressed between two surfaces, they fill microscopic gaps, creating a leak-proof seal. Key factors include:

Material flexibility (e.g., nitrile, silicone, or fluorocarbon).

Proper gland design (the groove where the O-ring sits).

Resistance to temperature, pressure, and chemicals.

Real-World Applications: From Mars Rovers to Your Kitchen Sink

Aerospace: O-rings seal fuel lines in rockets and maintain cabin pressure in aircraft.

Automotive: They prevent oil leaks in engines and seal air conditioning systems.

Medical: Silicone O-rings ensure sterile fluid paths in dialysis machines.

Household: They’re hidden in faucets, coffee makers, and even your refrigerator.

Case Study: The O-Ring That Saved a Mars Rover

In 2012, NASA’s Curiosity rover faced extreme Martian temperatures (-130°F to +70°F). Specially designed Viton® O-rings in its sampling system prevented freezing and cracking, enabling groundbreaking discoveries.

Future Innovations: Smarter, Tougher, Greener

Self-Healing Materials: Researchers are developing O-rings that repair minor cracks autonomously.

Eco-Friendly Options: Bio-based elastomers reduce environmental impact.

3D-Printed Custom Seals: On-demand printing for complex industrial needs.

Conclusion: Small Part, Big Impact

O-rings prove that size doesn’t define importance. Their reliability keeps industries running, saves lives, and even enables interplanetary exploration. Next time you brew coffee or drive to work, remember the tiny ring making it all possible.Great seals provide o rings and seals products can meet your requirements! Please mail : sale@gsealing.com

Hot Products

-

View More

View More

-

View More

View More

Magnetic Abs OEM Bearing Seals China Manufacturer

-

View More

View More

Automobile Brake Disc Wheel Bearing Seals China Supplier

-

View More

View More

EPDM rubber o-ring seal different size factory China manufacturer

-

View More

View More

Automotive Oil Filter Rubber Check Valve

-

View More

View More

HNBR O Ring Seal OEM Manufacturer China

-

View More

View More

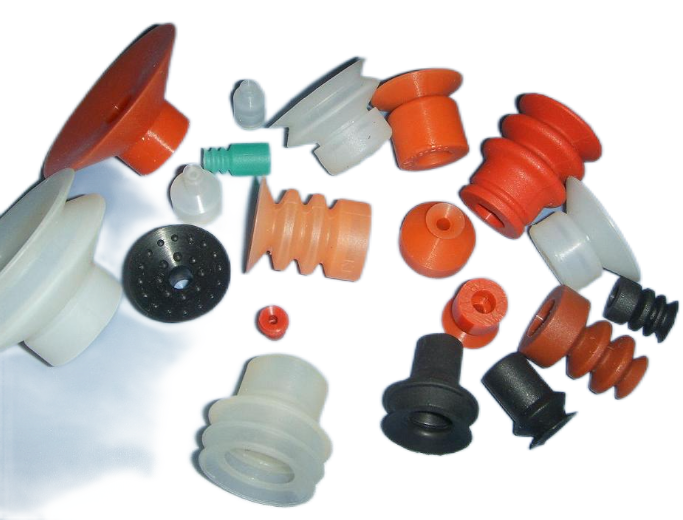

Rubber High Pressure Suction For Electronic Hand OEM China Factory

-

View More

View More

John Deere Tractor Cassette oil seal RWDR Manufacturer

-

View More

View More

High Pressure TCN Oil Seal for Excavator

-

View More

View More

Trailer Grease shaft rubber lip oil seal TB 11174

-

View More

View More

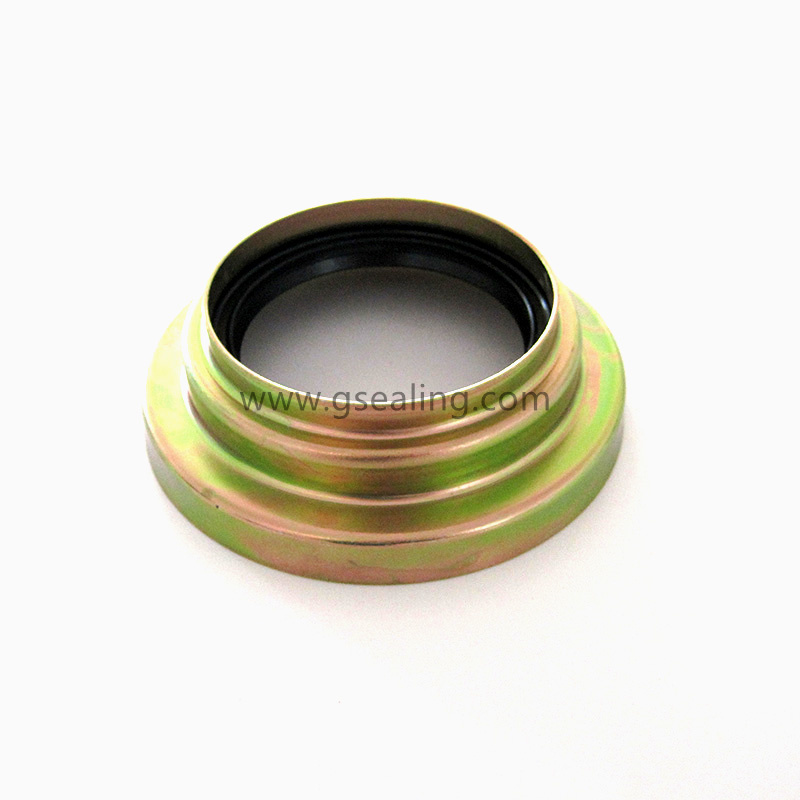

Ford New Holland Tractor Half Shaft Seal Retainer Assembly China Manufacturer

-

View More

View More

Irrigation Valley Valmont Gearbox Oil Seal China Supplier

-

View More

View More

High Quality Agriculture Machinery Rotation Oil Seal Kits

-

View More

View More

John Deer Grease Drive Shaft Oil Seal China Supplier

-

View More

View More

Tractor shaft combine oil seal