Rubber Gaskets and O-Rings: A Comparative Analysis

Rubber gaskets and O-rings are two widely used sealing components in industrial applications. Although both serve to prevent fluid leakage and isolate contaminants, they exhibit significant differences in structural design, application scenarios, and working principles. Below is a detailed analysis of both:

1. Rubber Gaskets

Definition: Flat sealing components made from elastic rubber materials (such as NBR, EPDM, or silicone), which can be manufactured in various shapes (round, square, or custom profiles).

Key Features:

Conformability: Adapts to irregular sealing surfaces, compensating for minor imperfections.

Compression Recovery: Achieves sealing through elastic deformation under compression.

Material Variety: Available in different hardness grades, temperature resistances, and chemical compatibilities.

Typical Applications:

Pipe flange connections

Electrical equipment waterproofing and dustproofing

Industrial machinery housing seals

Usage Guidelines:

Select appropriate rubber material based on medium compatibility.

Ensure uniform compression (typically 30%-40%).

Periodically inspect for compression set.

2. O-Rings

Definition: Elastic sealing rings with a circular cross-section, compliant with international standards (e.g., AS568, ISO 3601).

Key Features:

Dual Functionality: Suitable for both static and dynamic (reciprocating/rotary) sealing.

Pressure-Assisted Sealing: System pressure induces radial expansion, enhancing sealing effectiveness.

High Standardization: Globally standardized sizing ensures interchangeability.

Typical Applications:

Hydraulic/pneumatic system seals

Rotary shaft seals

Precision instrument sealing

Usage Guidelines:

Must precisely match groove dimensions.

For dynamic applications, consider surface finish and lubrication.

Avoid twisting or stretching during installation.

Technical Comparison

| Aspect | Rubber Gaskets | O- rings |

|---|---|---|

| Cross-Section | Flat profile | Circular cross-section |

| Sealing Mechanism | Compression-based | Elastic deformation + pressure-assisted |

| Operating Conditions | Low-pressure static sealing | High-pressure dynamic/static sealing |

| Standardization | Mostly custom-made | Highly standardized |

| Installation Requirements | Controlled compression needed | Precise groove matching required |

Engineering Recommendations

Selection Criteria:

Prefer O-rings for: High-pressure, dynamic sealing, standardized interfaces.

Choose gaskets for: Large sealing surfaces, non-standard interfaces, vibration damping.

Maintenance Tips:

Establish regular inspection intervals (recommended every 500 operating hours).

Monitor material aging indicators (replace if hardness change exceeds 15%).

Store away from direct sunlight and ozone exposure.

Conclusion

Rubber gaskets and O-rings play critical roles as fundamental sealing elements in industrial production. Understanding their differences and appropriate applications—combined with proper material selection based on operating conditions (pressure, temperature, medium, etc.) and adherence to standardized installation and maintenance procedures—ensures optimal sealing performance and long-term equipment reliability. With advancements in material technology, these traditional sealing solutions continue to evolve, providing more reliable sealing options for modern industrial equipment.

Hot Products

-

View More

View More

-

View More

View More

Magnetic Abs OEM Bearing Seals China Manufacturer

-

View More

View More

Automobile Brake Disc Wheel Bearing Seals China Supplier

-

View More

View More

EPDM rubber o-ring seal different size factory China manufacturer

-

View More

View More

Automotive Oil Filter Rubber Check Valve

-

View More

View More

HNBR O Ring Seal OEM Manufacturer China

-

View More

View More

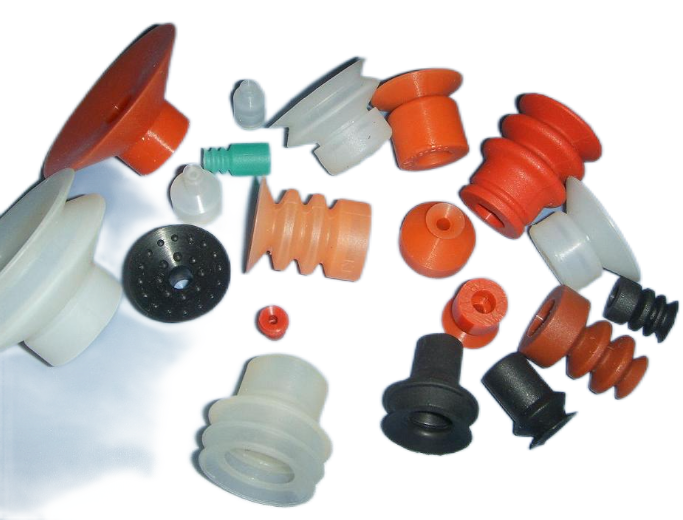

Rubber High Pressure Suction For Electronic Hand OEM China Factory

-

View More

View More

John Deere Tractor Cassette oil seal RWDR Manufacturer

-

View More

View More

High Pressure TCN Oil Seal for Excavator

-

View More

View More

Trailer Grease shaft rubber lip oil seal TB 11174

-

View More

View More

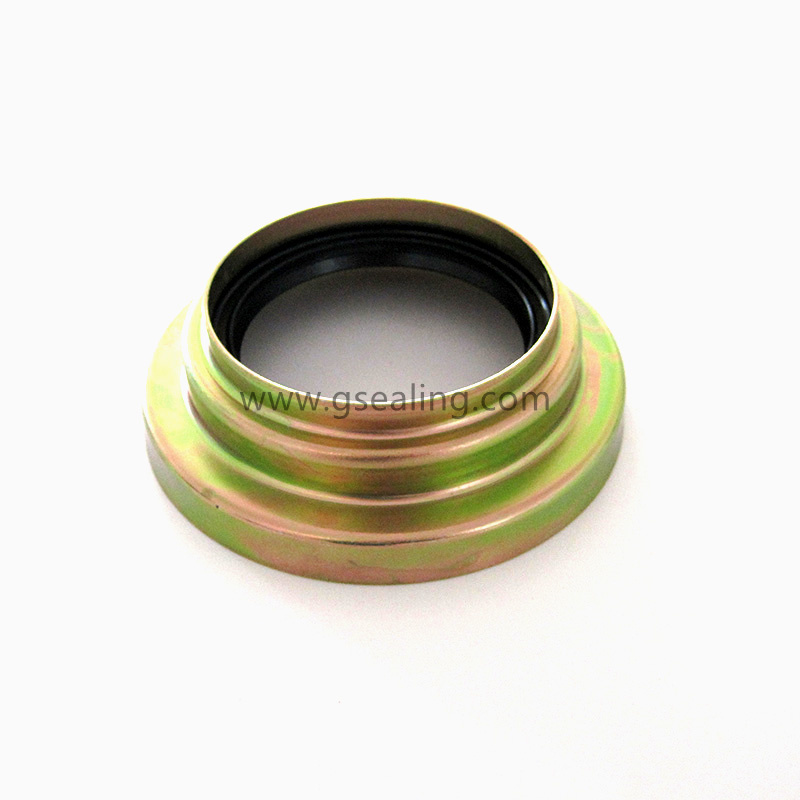

Ford New Holland Tractor Half Shaft Seal Retainer Assembly China Manufacturer

-

View More

View More

Irrigation Valley Valmont Gearbox Oil Seal China Supplier

-

View More

View More

High Quality Agriculture Machinery Rotation Oil Seal Kits

-

View More

View More

John Deer Grease Drive Shaft Oil Seal China Supplier

-

View More

View More

Tractor shaft combine oil seal