What kinds of rubber we choice for rubber seals

When selecting rubber materials for seals (e.g., oil seals, gaskets, O-rings), the choice depends on the operating environment, temperature range, chemical exposure, pressure, and mechanical stress. Below are the most common rubber types used for seals, their properties, and typical applications:

1. Nitrile Rubber (NBR)

Key Properties:

Excellent resistance to oils, fuels, and hydrocarbons.

Good abrasion resistance.

Temperature range: -40°C to +120°C (short-term up to 150°C).

Advantages:

Cost-effective, widely available.

Ideal for general-purpose sealing in oil or fuel systems.

Limitations:

Poor resistance to ozone, sunlight, and polar solvents (e.g., acetone).

Applications:

Engine oil seals, fuel system seals, hydraulic seals.

2. Fluoroelastomer (FKM/Viton)

Key Properties:

Exceptional heat and chemical resistance.

Resists oils, fuels, acids, and aggressive chemicals.

Temperature range: -20°C to +200°C (short-term up to 250°C).

Advantages:

Performs well in high-temperature and corrosive environments.

Limitations:

Expensive.

Poor low-temperature flexibility.

Applications:

High-temperature engine seals, aerospace seals, chemical-processing seals.

3. Silicone Rubber (VMQ)

Key Properties:

Extreme temperature tolerance (-60°C to +230°C).

Flexible at low temperatures.

Resists oxygen, ozone, and UV light.

Advantages:

Non-reactive with many chemicals.

Biocompatible (used in medical devices).

Limitations:

Poor tear strength and abrasion resistance.

Swells in hydrocarbon fuels/oils.

Applications:

High/low-temperature seals, food-grade seals, medical equipment.

4. Ethylene Propylene Diene Monomer (EPDM)

Key Properties:

Excellent resistance to water, steam, ozone, and weathering.

Temperature range: -50°C to +150°C.

Advantages:

Good for water-based and polar fluids (e.g., brake fluids, glycol).

Limitations:

Poor resistance to hydrocarbon oils and fuels.

Applications:

Coolant system seals, radiator hoses, outdoor weather seals.

5. Polyurethane (PU)

Key Properties:

Outstanding abrasion and tear resistance.

High load-bearing capacity.

Temperature range: -40°C to +100°C (varies by type).

Advantages:

Ideal for high-pressure, dynamic applications.

Limitations:

Degrades in hot water or humid environments.

Poor chemical resistance to acids/alkalis.

Applications:

Hydraulic seals, pneumatic seals, industrial machinery.

6. Hydrogenated Nitrile Rubber (HNBR)

Key Properties:

Enhanced heat/ozone resistance vs. standard NBR.

Temperature range: -40°C to +150°C (short-term up to 180°C).

Advantages:

Combines oil resistance of NBR with improved durability.

Limitations:

More expensive than NBR.

Applications:

Automotive timing belt seals, fuel injectors, refrigeration systems.

**7. Perfluoroelastomer (FFKM/Kalrez®)

Key Properties:

Ultimate chemical/thermal resistance.

Temperature range: -25°C to +300°C.

Advantages:

Resists almost all chemicals, including aggressive acids and bases.

Limitations:

Extremely high cost.

Applications:

Semiconductor manufacturing, oil/gas drilling, chemical reactors.

Key Selection Criteria

Temperature: Match the rubber’s operating range to the application.

Chemical Compatibility: Ensure resistance to fluids/chemicals in contact.

Pressure/Dynamic Load: Choose abrasion-resistant materials (e.g., PU, HNBR).

Cost: Balance performance needs with budget

Environmental Factors: UV, ozone, or moisture exposure may require EPDM or silicone.

Example Scenarios

Engine Oil Seal: Use NBR (standard) or FKM (high-temperature).

Coolant System Seal: Choose EPDM.

Aerospace Hydraulic Seal: Opt for FKM or FFKM.

Food-Grade Seal: Select Silicone or EPDM or FKM(high speed rotation seals)

By aligning material properties with your specific application requirements, you can ensure longevity, reliability, and cost-effectiveness of the seal.

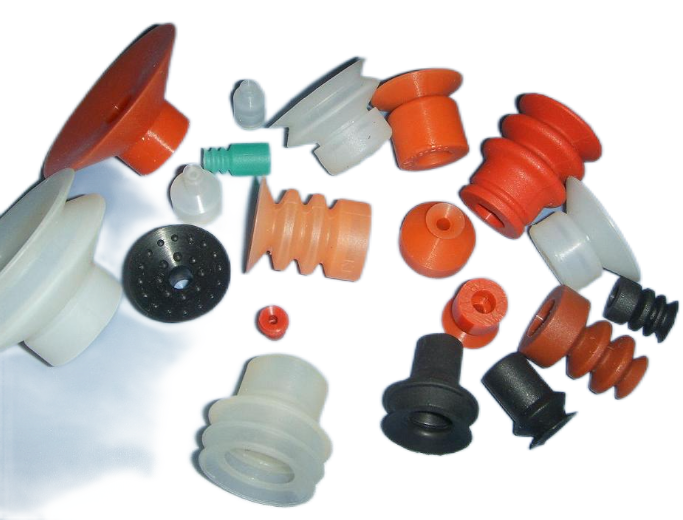

Hot Products

-

View More

View More

-

View More

View More

Magnetic Abs OEM Bearing Seals China Manufacturer

-

View More

View More

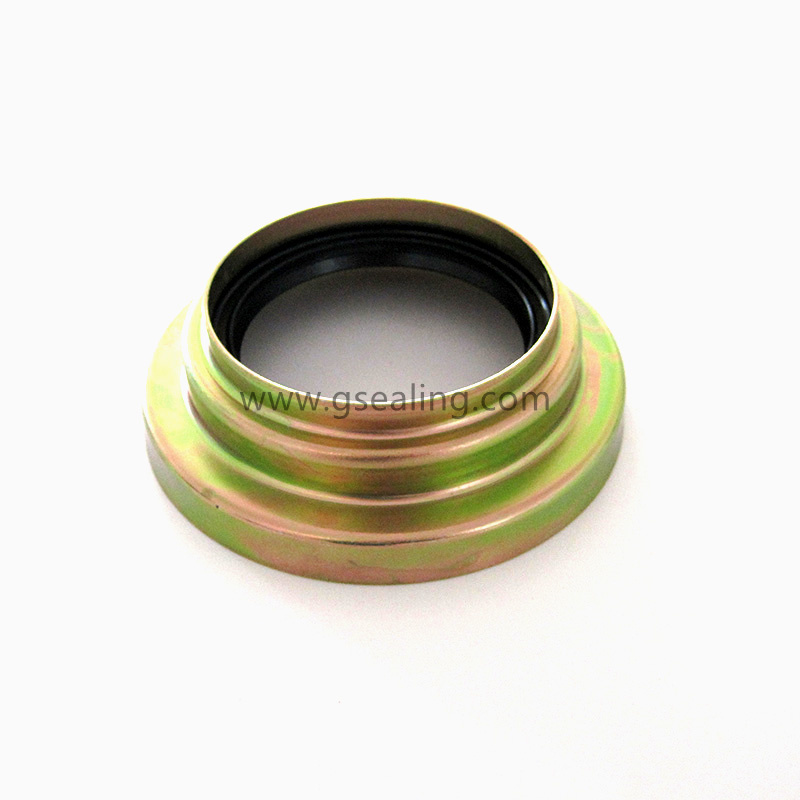

Automobile Brake Disc Wheel Bearing Seals China Supplier

-

View More

View More

EPDM rubber o-ring seal different size factory China manufacturer

-

View More

View More

Automotive Oil Filter Rubber Check Valve

-

View More

View More

HNBR O Ring Seal OEM Manufacturer China

-

View More

View More

Rubber High Pressure Suction For Electronic Hand OEM China Factory

-

View More

View More

John Deere Tractor Cassette oil seal RWDR Manufacturer

-

View More

View More

High Pressure TCN Oil Seal for Excavator

-

View More

View More

Trailer Grease shaft rubber lip oil seal TB 11174

-

View More

View More

Ford New Holland Tractor Half Shaft Seal Retainer Assembly China Manufacturer

-

View More

View More

Irrigation Valley Valmont Gearbox Oil Seal China Supplier

-

View More

View More

High Quality Agriculture Machinery Rotation Oil Seal Kits

-

View More

View More

John Deer Grease Drive Shaft Oil Seal China Supplier

-

View More

View More

Tractor shaft combine oil seal