Automotive Oil Seals: Functions and Applications Explained

Automotive Oil Seals: Functions and Applications Explained

1. Definition & Purpose

An automotive oil seal (also called a shaft seal or rotary seal) is a critical component designed to:

Prevent leakage of lubricants (oil, grease) from rotating shafts or bearings.

Block contaminants (dust, dirt, moisture) from entering mechanical systems.

Maintain lubrication efficiency and extend component lifespan.

2. Key Functions

Dynamic Sealing: Seals rotating/dynamic interfaces (e.g., crankshafts, axles).

Static Sealing: Seals stationary parts (e.g., engine covers).

Dual Protection: Advanced designs combine oil retention and dust exclusion (e.g., double-lipped seals).

3. Common Types

By Structure

Single-Lip Seal: Basic design for oil retention.

Double-Lip Seal: Adds a dust-exclusion lip (e.g., wheel hub seals).

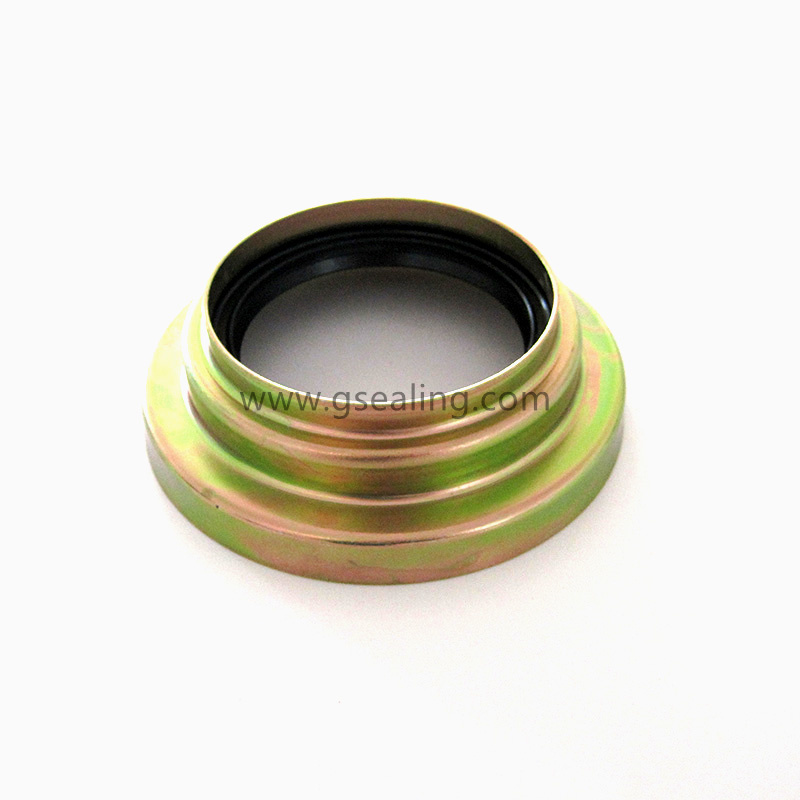

Metal-Cased Seal: Reinforced with a steel骨架 for durability (common in engines).

PTFE Seals: Low-friction, high-temperature resistance (e.g., turbochargers).

By Material

NBR (Nitrile Rubber): Standard for oil/fuel resistance (e.g., engine crankshaft seals).

FKM (Fluoroelastomer): High heat/chemical resistance (up to 250°C, for turbo systems).

ACM (Polyacrylate): Balanced heat/oil resistance (e.g., transmissions).

Silicone: Extreme temperature tolerance (‑60°C to 230°C).

4. Major Applications

| Component | Seal Type | Function |

|---|---|---|

| Engine | Crankshaft seal | Prevents oil leaks from engine block. |

| Transmission | Input/output shaft seal | Retains gearbox lubricant. |

| Differential | Pinion seal | Seals driveshaft interface. |

| Wheel Hub | Double-lipped seal | Protects bearings from dirt/water. |

| Turbocharger | PTFE/FKM seal | Withstands exhaust heat & pressure. |

5. Failure Signs & Causes

Symptoms: Oil leaks, grease contamination, abnormal noise.

Root Causes:

Material degradation (heat, ozone, or chemical exposure).

Shaft wear/misalignment (improper installation or imbalance).

Seal lip damage (abrasive particles or dry running).

6. Selection & Maintenance Tips

Installation:

Clean shaft/seal housing thoroughly.

Lubricate seal lips before assembly.

Use proper tools to avoid distortion.

Material Choice: Match to operating conditions (temperature, speed, media).

Replacement: Always inspect seals during routine maintenance (e.g., oil changes).

7. Industry Trends

Smart Seals: Integrated sensors for real-time leak detection.

Eco-Friendly Materials: Bio-based elastomers for sustainability.

Long-Life Designs: Hybrid seals combining PTFE and rubber.

Why It Matters: Oil seals are small but vital—failure can lead to costly engine/transmission damage. Understanding their role ensures proper vehicle maintenance and performance.

Hot Products

-

View More

View More

-

View More

View More

Magnetic Abs OEM Bearing Seals China Manufacturer

-

View More

View More

Automobile Brake Disc Wheel Bearing Seals China Supplier

-

View More

View More

EPDM rubber o-ring seal different size factory China manufacturer

-

View More

View More

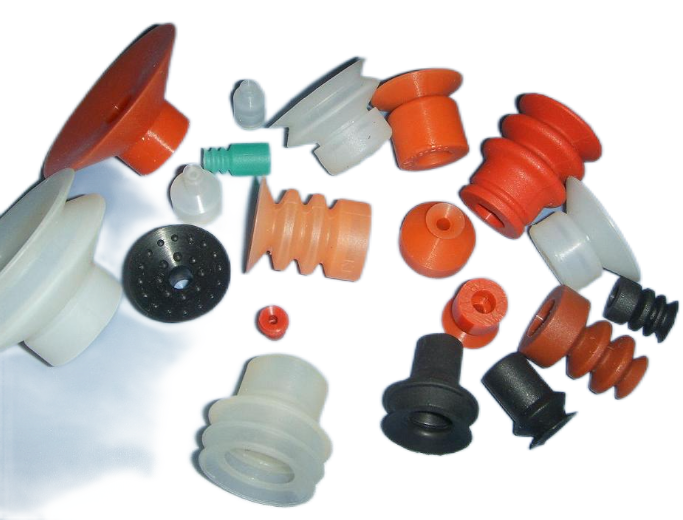

Automotive Oil Filter Rubber Check Valve

-

View More

View More

HNBR O Ring Seal OEM Manufacturer China

-

View More

View More

Rubber High Pressure Suction For Electronic Hand OEM China Factory

-

View More

View More

John Deere Tractor Cassette oil seal RWDR Manufacturer

-

View More

View More

High Pressure TCN Oil Seal for Excavator

-

View More

View More

Trailer Grease shaft rubber lip oil seal TB 11174

-

View More

View More

Ford New Holland Tractor Half Shaft Seal Retainer Assembly China Manufacturer

-

View More

View More

Irrigation Valley Valmont Gearbox Oil Seal China Supplier

-

View More

View More

High Quality Agriculture Machinery Rotation Oil Seal Kits

-

View More

View More

John Deer Grease Drive Shaft Oil Seal China Supplier

-

View More

View More

Tractor shaft combine oil seal