Differences Between Dynamic Seals and Static Seals

Dynamic seals and static seals are two types of sealing elements with distinct applications, designs, and performance requirements. Below is a detailed comparison:

1. Application Scenarios

Dynamic Seals

Purpose: Used between components with relative motion (e.g., rotating shafts, reciprocating pistons, oscillating rods).

Typical Applications: Hydraulic cylinder rods, engine crankshafts, pump shafts, valve stems, etc.

Static Seals

Purpose: Used between fixed components to prevent fluid leakage or contamination.

Typical Applications: Flange connections, pipe joints, end covers, etc.

2. Design Features

Dynamic Seals

Material: Requires wear resistance (e.g., polyurethane, PTFE, rubber with reinforced fibers) and a low friction coefficient.

Structure: Often designed as lip seals (e.g., oil seals), composite seals (e.g., Glyd rings, Step seals), or wavy structures to accommodate motion and retain lubrication.

Surface Treatment: Contact surfaces may require special coatings (e.g., Teflon) to reduce wear.

Static Seals

Material: Focuses on elasticity and compression set resistance (e.g., nitrile rubber, silicone, fluorocarbon rubber).

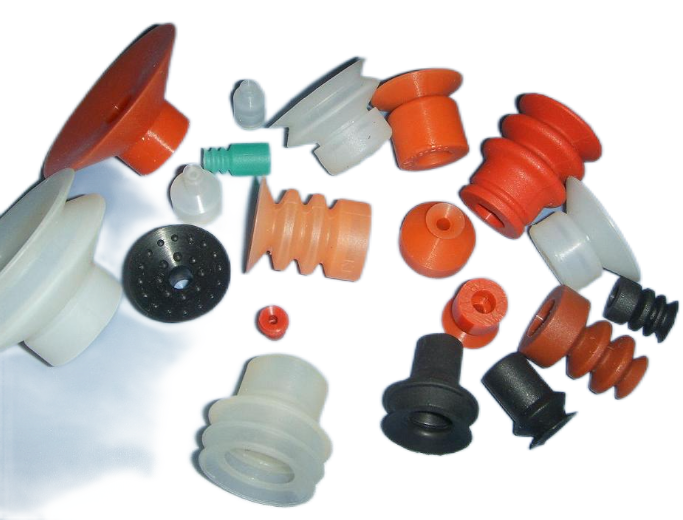

Structure: Typically simple shapes (e.g., O-rings, flat gaskets, rectangular gaskets) that rely on compression to fill gaps

3. Performance Requirements

Dynamic Seals

Wear Resistance: Must endure long-term friction and wear.

Temperature Resistance: May face higher temperatures due to frictional heat.

Lubrication Needs: Usually requires lubricating media or self-lubricating designs.

Static Seals

Compression Recovery: Must maintain elasticity after prolonged compression to avoid leakage.

Media Resistance: Material selection depends on contact fluids (oil, water, chemicals).

Creep Resistance: Prevents permanent deformation under long-term static pressure.

4. Failure Modes

Dynamic Seals

Common failures: Wear, lip cracking, dry friction due to insufficient lubrication.

Static Seals

Common failures: Compression set, aging/cracking, extrusion due to improper installation.

5. Installation & Maintenance

Dynamic Seals

Installation must consider orientation (e.g., lip direction facing the pressure side).

Requires periodic wear inspection and lubrication replenishment.

Static Seals

Installation requires controlled compression (e.g., O-rings typically compressed 20%-30%).

Maintenance involves direct replacement without dynamic adjustments.

Summary

| Feature | Dynamic Seals | Static Seals |

|---|---|---|

| Motion State | Relative movement (rotation, reciprocation) | Fixed, no movement |

| Design Focus | Wear resistance, low friction | High elasticity, compression resistance |

| Common Types | Oil seals, Glyd rings, Step seals | O-rings, flat gaskets, sealants |

| Failure Risks | Wear, overheating | Aging, compression set |

Selection should be based on actual working conditions (pressure, temperature, media, motion type) to ensure sealing reliability and longevity.

echnical Challenges of Dynamic Seals

Dynamic seals must maintain long-term sealing performance under relative motion, presenting key technical challenges in friction and wear control, material adaptability, structural optimization, and compatibility with operating conditions. Below is a detailed analysis of the main challenges and their solutions.

1. Friction and Wear Control

Challenges

Heat generation from high friction: Frictional heat accelerates material degradation (e.g., rubber hardening, PTFE deformation).

Lubrication failure: Dry friction or insufficient lubrication causes seal lip wear (e.g., "stick-slip" in hydraulic cylinders).

Abrasive wear: Contaminants (e.g., dust, metal particles) can scratch sealing surfaces.

Solutions

Material optimization: Use self-lubricating materials (e.g., filled PTFE, polyurethane composites) or surface coatings (e.g., DLC diamond-like carbon).

Lubrication design: Integrate micro-oil grooves or oil reservoirs (e.g., spring-energized seals) or opt for lubrication-free engineering plastics (e.g., PEEK).

Contamination protection: Add wiper seals or multi-stage sealing structures to block contaminants.

2. Material Adaptability

Challenges

Media compatibility: Must resist oils, water, and chemical corrosion (e.g., additives in hydraulic fluids, acidic/alkaline media).

Temperature extremes: Low temperatures (< -40°C) cause rubber brittleness, while high temperatures (> 150°C) lead to softening or decomposition.

Dynamic fatigue: Repeated compression-relaxation cycles cause permanent deformation (e.g., compression set in NBR rubber).

Solutions

Composite materials:

High-temperature: Fluorocarbon rubber (FKM) or perfluoroelastomers (FFKM).

Chemical resistance: PTFE or PTFE-coated rubber.

Reinforced structures: Add fiber reinforcement (e.g., aramid fibers) to improve extrusion resistance.

3. Structural Design Challenges

Challenges

Diverse motion types: Rotational, reciprocating, and oscillating motions require different designs (e.g., rotary shaft seals, reciprocating Step seals).

Pressure fluctuations: High-frequency pressure pulses (e.g., hydraulic system surges) can cause seal lip flipping or extrusion.

Space constraints: Compact designs must balance sealing performance and size (e.g., micro hydraulic cylinder seals).

Solutions

Combination seals:

Glyd Ring: PTFE ring + O-ring for low friction and elasticity.

Spring-Energized Seal: Metal spring + sealing lip for high pressure and temperature stability.

Bio-inspired designs: Mimic natural sealing mechanisms (e.g., shark-skin textures) to reduce fluid drag.

4. Compatibility with Complex Operating Conditions

Challenges

Extreme pressure: Ultra-high pressure (> 50 MPa) causes material extrusion (e.g., O-rings squeezing into gaps).

Speed limits: High-speed rotation (> 20 m/s) leads to hydrodynamic lubrication failure (e.g., oil seal leakage).

Multi-physics coupling: Combined thermal-mechanical-chemical effects accelerate failure (e.g., chemical swelling under high temperature/pressure).

Solutions

Pressure staging: Use multi-stage seals to distribute pressure (e.g., stepped seals in high-pressure pumps).

Hydrodynamic design: Optimize lip angles (e.g., helical grooves in oil seals) to enhance fluid film formation.

Multiphysics simulation: Finite element analysis (FEA) to model thermo-mechanical behavior.

5. Service Life and Reliability

Challenges

Life prediction difficulty: Wear rates vary significantly with operating conditions, making modeling unreliable.

Sudden failures: Micro-cracks or localized wear can cause instant leaks (e.g., spacecraft seal failure).

Solutions

Condition monitoring: Embed fiber-optic sensors for real-time wear and temperature tracking.

Accelerated life testing: Simulate long-term conditions via high-frequency cycling tests.

Typical Application Comparisons

| Operating Condition | Technical Challenge | Solution |

|---|---|---|

| High-speed rotation | Lubrication failure, lip deformation | Helical groove seals, gas-liquid lubrication |

| High-pressure reciprocation | Material extrusion, pressure fatigue | Metal-reinforced seals, PU+PTFE composites |

| Corrosive media | Chemical swelling, degradation | Perfluoroelastomers (FFKM), surface coatings |

Future Technology Trends

Smart seals: Integrated sensors for self-diagnosis of wear.

Advanced materials: Graphene composites, self-healing supramolecular materials.

Eco-friendly designs: Oil-free self-lubricating seals to reduce pollution.

Breakthroughs in dynamic seals require interdisciplinary innovation in materials science, mechanical engineering, and simulation technology to meet the demanding needs of advanced applications (e.g., aerospace, electric vehicles).

Hot Products

-

View More

View More

-

View More

View More

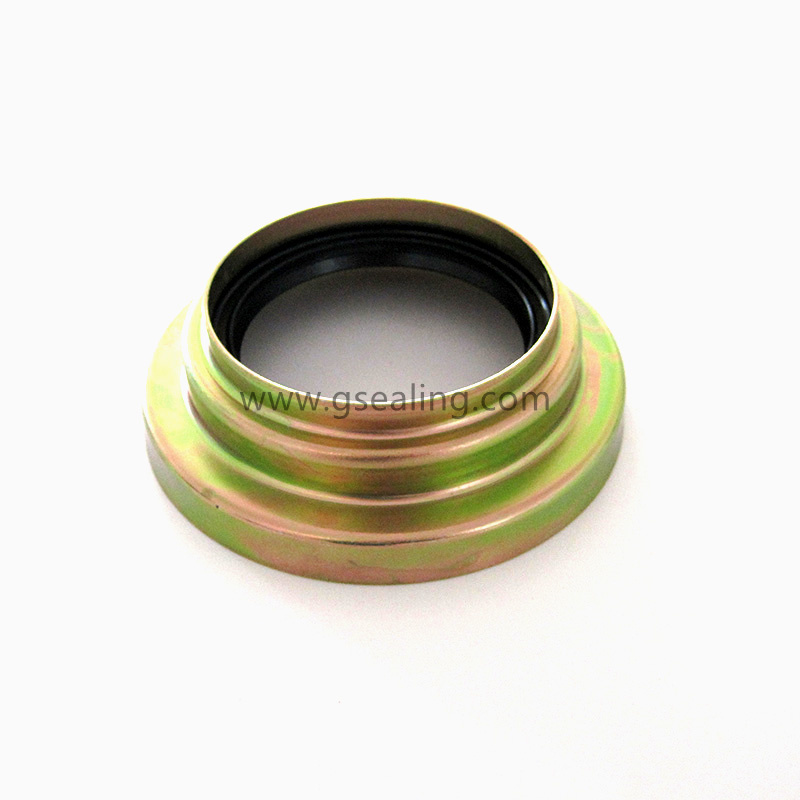

Magnetic Abs OEM Bearing Seals China Manufacturer

-

View More

View More

Automobile Brake Disc Wheel Bearing Seals China Supplier

-

View More

View More

EPDM rubber o-ring seal different size factory China manufacturer

-

View More

View More

Automotive Oil Filter Rubber Check Valve

-

View More

View More

HNBR O Ring Seal OEM Manufacturer China

-

View More

View More

Rubber High Pressure Suction For Electronic Hand OEM China Factory

-

View More

View More

John Deere Tractor Cassette oil seal RWDR Manufacturer

-

View More

View More

High Pressure TCN Oil Seal for Excavator

-

View More

View More

Trailer Grease shaft rubber lip oil seal TB 11174

-

View More

View More

Ford New Holland Tractor Half Shaft Seal Retainer Assembly China Manufacturer

-

View More

View More

Irrigation Valley Valmont Gearbox Oil Seal China Supplier

-

View More

View More

High Quality Agriculture Machinery Rotation Oil Seal Kits

-

View More

View More

John Deer Grease Drive Shaft Oil Seal China Supplier

-

View More

View More

Tractor shaft combine oil seal