Principle of Hydraulic seals

The Hydraulic oil seal is generally made of rubber sealing material. The seal ring has simple structure, good sealing performance and low friction. It can be used for linear reciprocating and rotary motion, but it is more used for fixing seals, such as seals between pipelines, cylinder heads and cylinder liners. Or suitable for low-grade and non-critical devices.

In daily operation, fatigue of hydraulic equipment always exists, so regular stop inspection and maintenance are required during operation. The cylinder barrel of the cylinder seal often needs professional maintenance, overhaul and maintenance to improve the service life of the cylinder seal and the seal performance.

So, what is the correct maintenance of the rubber seal of the oil cylinder?

1. The hydraulic cylinder of the seal shall be replaced with hydraulic oil regularly to clean the filter screen and ensure the cleanliness standard;

2, the use of oil cylinder equipment must adjust the system temperature, to avoid affecting the service life of the seal;

3. The air in the system shall be removed and all systems shall be preheated at the same time to avoid oil cylinder failure.

4. The bolts and threads of each connection system shall be regularly overhauled in the follow-up to avoid loosening and causing faults.

5, and pay attention to the oil components to maintain lubrication, avoid causing dry friction;

6, protect the outer surface of the piston rod, prevent knock and scratch damage to the seal, clean up the oil cylinder dynamic seal dust ring parts and bare sediment on the piston rod.

Hot Products

-

View More

View More

-

View More

View More

Magnetic Abs OEM Bearing Seals China Manufacturer

-

View More

View More

Automobile Brake Disc Wheel Bearing Seals China Supplier

-

View More

View More

EPDM rubber o-ring seal different size factory China manufacturer

-

View More

View More

Automotive Oil Filter Rubber Check Valve

-

View More

View More

HNBR O Ring Seal OEM Manufacturer China

-

View More

View More

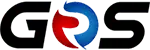

Rubber High Pressure Suction For Electronic Hand OEM China Factory

-

View More

View More

John Deere Tractor Cassette oil seal RWDR Manufacturer

-

View More

View More

High Pressure TCN Oil Seal for Excavator

-

View More

View More

Trailer Grease shaft rubber lip oil seal TB 11174

-

View More

View More

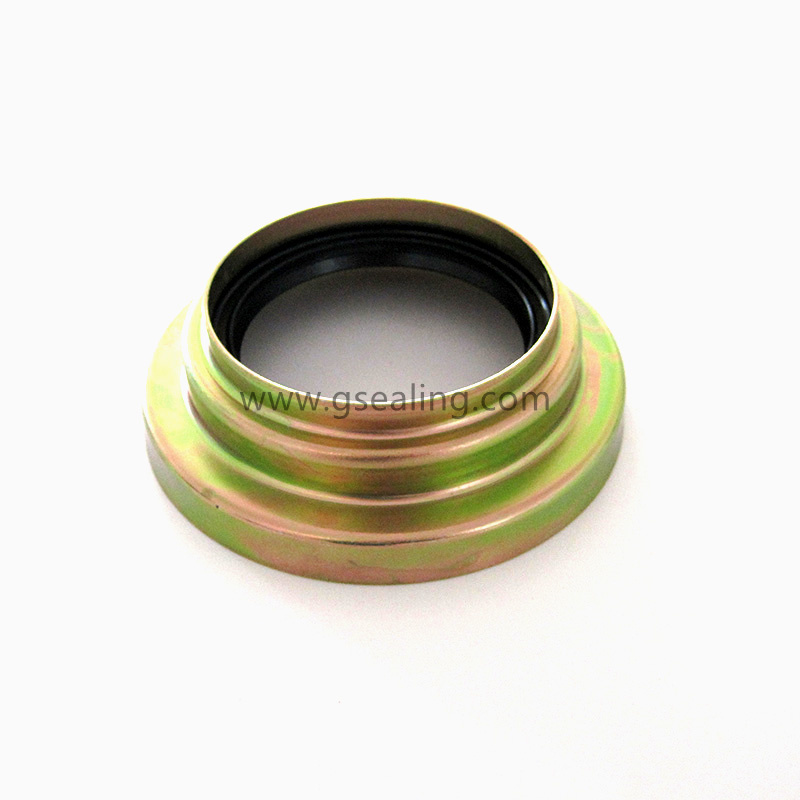

Ford New Holland Tractor Half Shaft Seal Retainer Assembly China Manufacturer

-

View More

View More

Irrigation Valley Valmont Gearbox Oil Seal China Supplier

-

View More

View More

High Quality Agriculture Machinery Rotation Oil Seal Kits

-

View More

View More

John Deer Grease Drive Shaft Oil Seal China Supplier

-

View More

View More

Tractor shaft combine oil seal