Magnetic bearing seals presentation and features

Magnetic oil seal is a product designed after years of research and experiment. It creatively uses modular magnetic compensation system and new material sealing technology, and easy installation can solve the problems that have been difficult to eradicate in industrial history. It not only responds to the national policy of green environmental protection for product transformation and upgrading, but also meets the 5S management requirements of factories and enterprises.

Traditional lip seal products are bound to have friction with the shaft surface in application, which is easy to fail in application. It cannot effectively prevent the bearing cavity from being polluted, and the service life is generally short and difficult to control. When the lip seal leaks, the loss of lubricating oil will bring disastrous consequences to bearings and equipment. Equipment damage caused by severe wear and tear will inevitably increase the repair cost.

Magnetic oil seal is designed with magnetic technology, mechanical seal concept and full floating sealing surface structure. Simple overall structure, convenient installation and less power consumption. Low consumption of dynamic and static rings. The joint surfaces of the dynamic and static rings are always in close contact, and effective sealing can be realized even under large shaft runout. Replacing skeleton oil seal with magnetic seal is the inevitable development direction of shaft seal technology.

Product features

1. The design of magnetic compensation seal is suitable for lubrication or dry friction, with zero leakage.

2. The magnetic oil seal has no requirement on the surface hardness of the shaft and will not wear the shaft.

3. The linear speed of magnetic oil seal can reach 50 m/s.

4. The service life of magnetic oil seal is longer than that of traditional oil seal, with a minimum of 28000h h.

Hot Products

-

View More

View More

-

View More

View More

Magnetic Abs OEM Bearing Seals China Manufacturer

-

View More

View More

Automobile Brake Disc Wheel Bearing Seals China Supplier

-

View More

View More

EPDM rubber o-ring seal different size factory China manufacturer

-

View More

View More

Automotive Oil Filter Rubber Check Valve

-

View More

View More

HNBR O Ring Seal OEM Manufacturer China

-

View More

View More

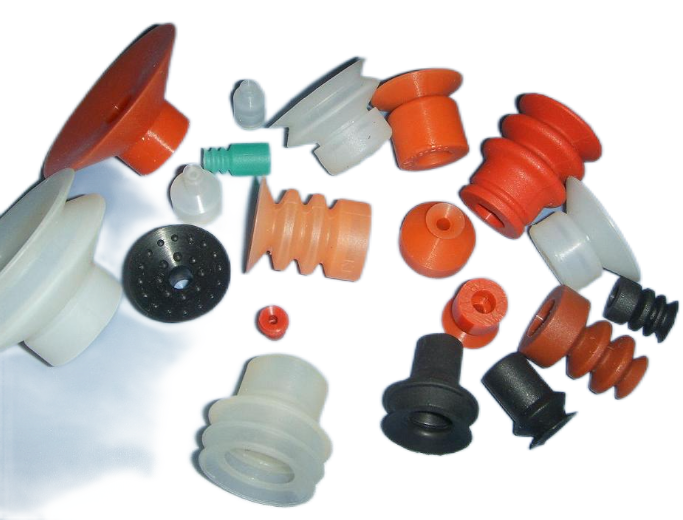

Rubber High Pressure Suction For Electronic Hand OEM China Factory

-

View More

View More

John Deere Tractor Cassette oil seal RWDR Manufacturer

-

View More

View More

High Pressure TCN Oil Seal for Excavator

-

View More

View More

Trailer Grease shaft rubber lip oil seal TB 11174

-

View More

View More

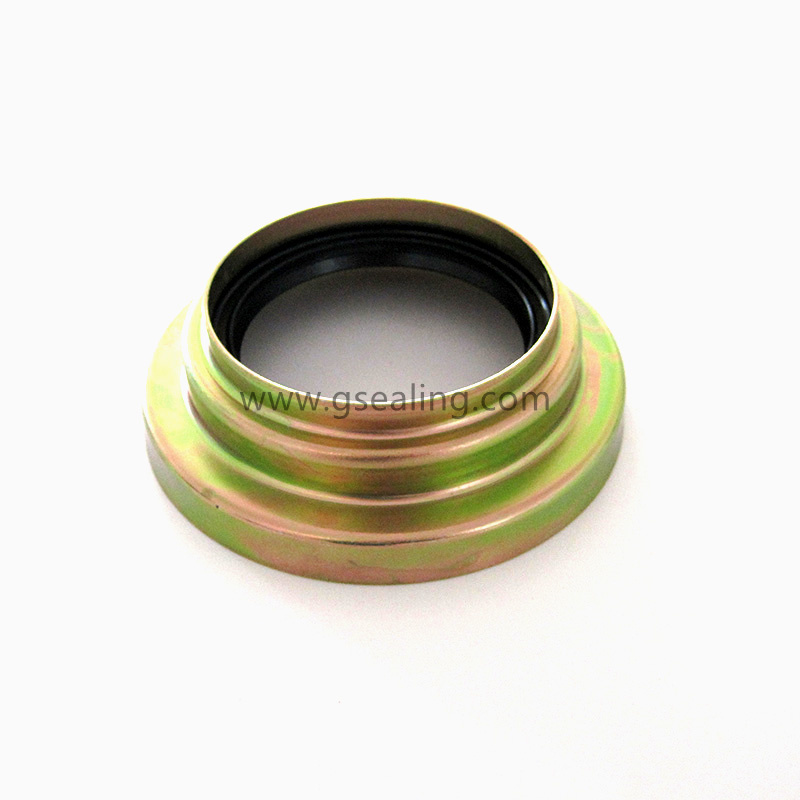

Ford New Holland Tractor Half Shaft Seal Retainer Assembly China Manufacturer

-

View More

View More

Irrigation Valley Valmont Gearbox Oil Seal China Supplier

-

View More

View More

High Quality Agriculture Machinery Rotation Oil Seal Kits

-

View More

View More

John Deer Grease Drive Shaft Oil Seal China Supplier

-

View More

View More

Tractor shaft combine oil seal