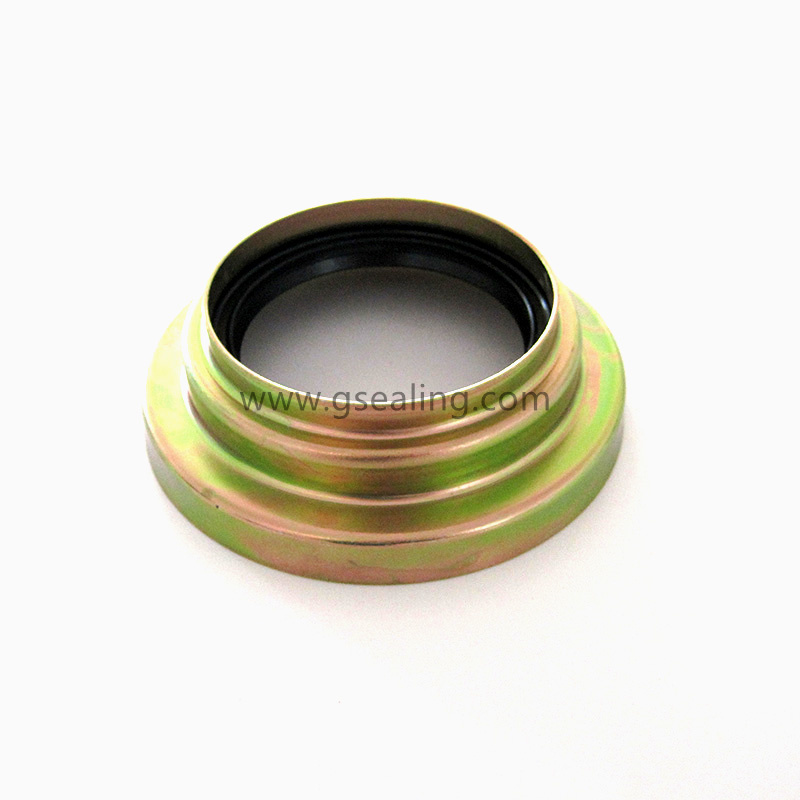

OIL SEAL design type

When it comes to OIL SEAL design, there are several key factors that need to be considered. The first is the type of seal material, which can significantly impact its performance and durability. The second is the design of the sealing surface, which must be smooth and free from imperfections in order to ensure a tight seal.

TA, SA, TB, TC, TG, SB, and TCY are all common types of OIL SEAL design. Each type has its own unique characteristics and advantages, making them suitable for different applications. For example, TA and SB seals are designed for use in reciprocating rod applications, while TB and TC seals are suitable for rotary shafts. TG seals are often used in high-pressure applications, and SA seals are commonly found in pneumatic systems.

When selecting an OIL SEAL design for a specific application, it is important to consider the operating conditions, such as the type of fluid being sealed, the pressure and temperature ranges, and the specific motion being sealed. For example, seals that are suitable for low-temperature applications may not perform well at high temperatures, and seals that are designed for static applications may not be suitable for dynamic sealing.

In addition to the type of seal material and design, the selection of appropriate gaskets, spacers, and backup rings can also have a significant impact on the performance of the sealing system. These components must be compatible with the seal material and have the appropriate dimensions to ensure a tight seal.

Overall, the selection of an appropriate OIL SEAL design for a specific application requires a thorough understanding of the sealing requirements and operating conditions. It is essential to consult with a professional engineer or manufacturer who has experience in sealing systems to ensure that the right seal is chosen for the specific application.

Hot Products

-

View More

View More

-

View More

View More

Magnetic Abs OEM Bearing Seals China Manufacturer

-

View More

View More

Automobile Brake Disc Wheel Bearing Seals China Supplier

-

View More

View More

EPDM rubber o-ring seal different size factory China manufacturer

-

View More

View More

Automotive Oil Filter Rubber Check Valve

-

View More

View More

HNBR O Ring Seal OEM Manufacturer China

-

View More

View More

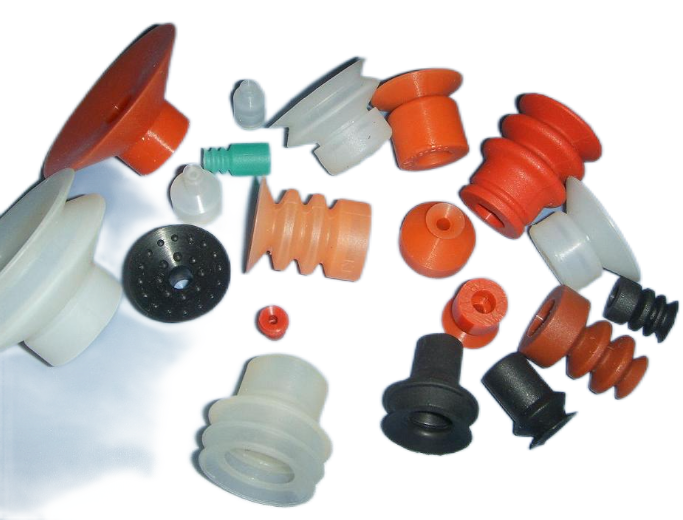

Rubber High Pressure Suction For Electronic Hand OEM China Factory

-

View More

View More

John Deere Tractor Cassette oil seal RWDR Manufacturer

-

View More

View More

High Pressure TCN Oil Seal for Excavator

-

View More

View More

Trailer Grease shaft rubber lip oil seal TB 11174

-

View More

View More

Ford New Holland Tractor Half Shaft Seal Retainer Assembly China Manufacturer

-

View More

View More

Irrigation Valley Valmont Gearbox Oil Seal China Supplier

-

View More

View More

High Quality Agriculture Machinery Rotation Oil Seal Kits

-

View More

View More

John Deer Grease Drive Shaft Oil Seal China Supplier

-

View More

View More

Tractor shaft combine oil seal