Application of Rubber Injection Molding Press in Vulcanization of EPDM

Abstract: The application of two different types of rubber injection molding press (A-type and B-type) in the vulcanization of ethylene propylene diene monomer (EPDM)was compared. A-type injection molding press was suitable for pure rubber products, while B-type injection molding press was suitable for rubber products with complex structures and metal inserts. During production, the problems such as difficulties in feeding, leakage of the rubber material, mold sticking and concave shrinkage holes at the injection port of the finished product, could be solved by improving the feeding port,changing injection parameters,cleaning the mold, and applying Teflon.

Key words: rubber injection molding press; EPDM SEAL; structure; parameter

YIWU GREAT SEAL RUBBER PRODUCTS COMPANY

Hot Products

-

View More

View More

-

View More

View More

Magnetic Abs OEM Bearing Seals China Manufacturer

-

View More

View More

Automobile Brake Disc Wheel Bearing Seals China Supplier

-

View More

View More

EPDM rubber o-ring seal different size factory China manufacturer

-

View More

View More

Automotive Oil Filter Rubber Check Valve

-

View More

View More

HNBR O Ring Seal OEM Manufacturer China

-

View More

View More

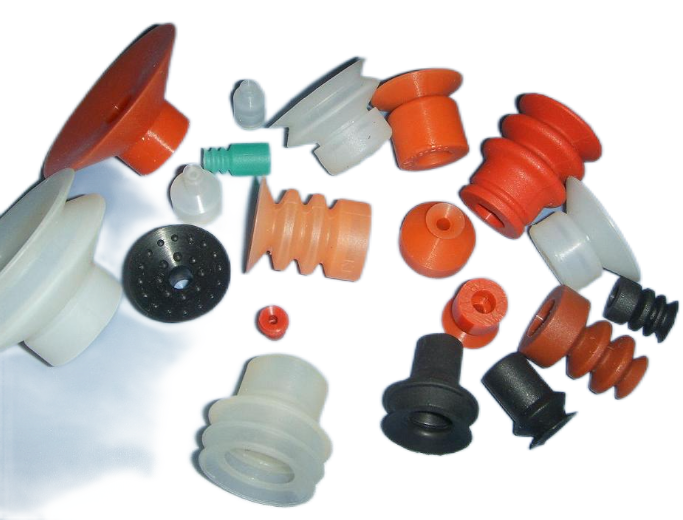

Rubber High Pressure Suction For Electronic Hand OEM China Factory

-

View More

View More

John Deere Tractor Cassette oil seal RWDR Manufacturer

-

View More

View More

High Pressure TCN Oil Seal for Excavator

-

View More

View More

Trailer Grease shaft rubber lip oil seal TB 11174

-

View More

View More

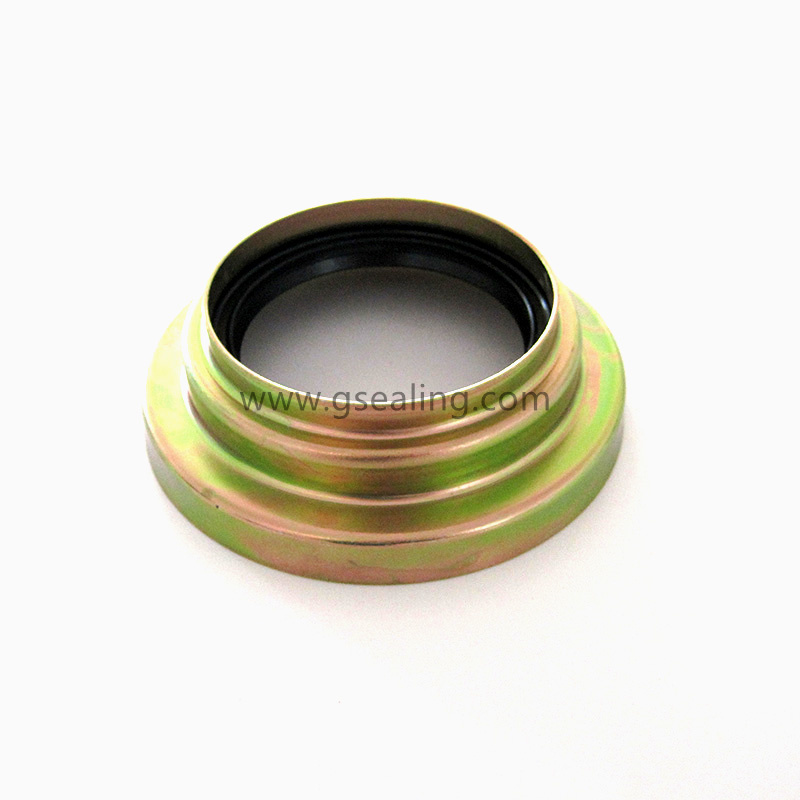

Ford New Holland Tractor Half Shaft Seal Retainer Assembly China Manufacturer

-

View More

View More

Irrigation Valley Valmont Gearbox Oil Seal China Supplier

-

View More

View More

High Quality Agriculture Machinery Rotation Oil Seal Kits

-

View More

View More

John Deer Grease Drive Shaft Oil Seal China Supplier

-

View More

View More

Tractor shaft combine oil seal