Solution to Oil Leakage of Gearbox Oil Seal?

Mechanical transmission is the most common in mechanical engineering. It is widely used to transmit force and friction transmission mainly by friction force of machine parts, including belt transmission, rope transmission and friction wheel transmission. Basic product classification: reducer, brake, clutch, coupling, stepless speed changer, lead screw and slide rail etc.

And gear transmission is one of the main transmission modes of mechanical transmission. Its running state will directly affect the working state of mechanical system. The maintenance of gear is to reduce the wear and tear in transmission and also to improve the life expectancy.

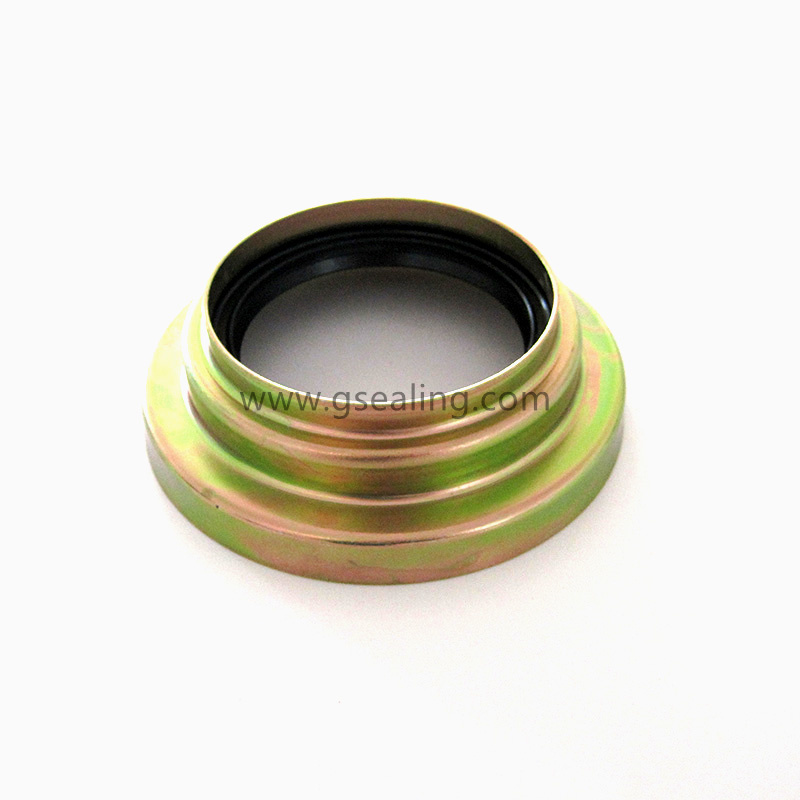

Oil leakage from gearbox oil seal is common and difficult to cure.

The traditional way is to replace the oil seal, which costs thousands of dollars each time and takes three to four days to complete. For the power transmission mechanism of speed reducer, which is an important equipment cluster in cement enterprises, daily maintenance and management are more important. The common problems are the wear of bearing seats, gear damage, oil leakage of dynamic and static seals, and damage of skeleton oil seals.

Ninety percent of the oil leakage is caused by oil seal corrosion and aging, especially rubber oil seals will lose plasticizer due to long-term temperature changes caused by alternating changes in temperature. The final result is that the oil seal shrinks and hardens, resulting in loss of elasticity and even more serious breakage. However, breakage generally does not occur. When oil leakage occurs, we will find it during maintenance and will not deal with it until breakage occurs.

Regular inspection, correct installation and adding lubricant can effectively increase the service life of the oil seal, but fundamentally speaking, a good oil seal should be selected, otherwise the symptoms will not be treated at the root of the problem and the oil seal will be replaced. Frequent replacement of oil seals takes time and effort.

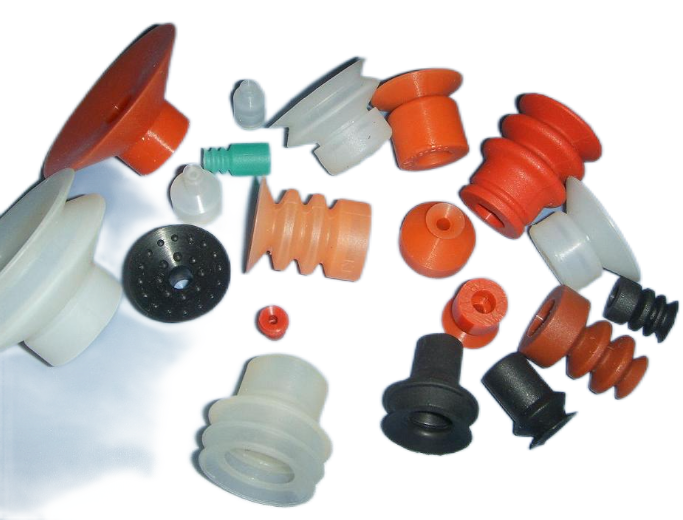

Hot Products

-

View More

View More

-

View More

View More

Magnetic Abs OEM Bearing Seals China Manufacturer

-

View More

View More

Automobile Brake Disc Wheel Bearing Seals China Supplier

-

View More

View More

EPDM rubber o-ring seal different size factory China manufacturer

-

View More

View More

Automotive Oil Filter Rubber Check Valve

-

View More

View More

HNBR O Ring Seal OEM Manufacturer China

-

View More

View More

Rubber High Pressure Suction For Electronic Hand OEM China Factory

-

View More

View More

John Deere Tractor Cassette oil seal RWDR Manufacturer

-

View More

View More

High Pressure TCN Oil Seal for Excavator

-

View More

View More

Trailer Grease shaft rubber lip oil seal TB 11174

-

View More

View More

Ford New Holland Tractor Half Shaft Seal Retainer Assembly China Manufacturer

-

View More

View More

Irrigation Valley Valmont Gearbox Oil Seal China Supplier

-

View More

View More

High Quality Agriculture Machinery Rotation Oil Seal Kits

-

View More

View More

John Deer Grease Drive Shaft Oil Seal China Supplier

-

View More

View More

Tractor shaft combine oil seal