Mechanical seals

Professional mechnical seal manufacturer yiwu great seal rubber products company

Mechanical seals working in liquid medium generally rely on the liquid film formed by liquid medium between the friction surfaces of moving and stationary rings for lubrication. Therefore, it is necessary to maintain the liquid film between the friction surfaces to ensure the stable operation of the mechanical seal and prolong its service life.

According to different conditions, the friction between the dynamic and static rings of mechanical seal will be as follows:

(1) dry friction:

There is no liquid entering the sliding friction surface, so there is no liquid film, only dust, oxide layer and adsorbed gas molecules. When the moving and static rings are running, the result is that the friction surface will heat up and wear up, resulting in leakage.

(2) Boundary lubrication:

When the pressure between the moving and stationary rings increases or the ability of liquid to form a liquid film on the friction surface is poor, the liquid will be squeezed out of the gap. Because the surface is not absolutely flat, but uneven, there is contact wear in the bulge, while the lubrication performance of liquid is maintained in the recess, resulting in boundary lubrication. The wear and heat of boundary lubrication is moderate.

(3) Semi-liquid lubrication:

There is liquid in the pit of the sliding surface, and a thin liquid film is maintained between the contact surfaces, so the heating and wear conditions are good. Because the liquid film between the moving and stationary rings has surface tension at its outlet, the leakage of liquid is limited.

(4) Complete liquid lubrication:

When the pressure between the moving and static rings is insufficient, and the gap increases, the liquid film thickens, and there is no solid contact at this time, so there is no friction phenomenon. However, in this case, the gap between the moving ring and the static ring is large, so the sealing effect cannot be achieved and the leakage is serious. This kind of situation is generally not allowed in practical application (except for mechanical seal of controlled membrane).

Most of the working conditions between the dynamic and static rings of mechanical seal are in boundary lubrication and semi-liquid lubrication, and semi-liquid lubrication can obtain the best sealing effect under the condition of minimum friction coefficient, that is, satisfactory wear and heat generation.

In order to make the mechanical seal work under good lubrication conditions, factors such as medium characteristics, pressure, temperature and sliding speed should be considered comprehensively. However, selecting appropriate pressure between the moving and static rings, reasonable lubrication structure and improving the friction surface quality of the moving and static rings are also important factors to ensure the effective work of the seal.

Several structures for strengthening lubrication

1. End face eccentricity:

In general mechanical seals, the center of the moving ring, the center of the stationary ring and the center line of the shaft are all in a straight line. If the end face center of one of the moving ring or the stationary ring is made to be offset from the center line of the shaft by a certain distance, the lubricating fluid can be continuously brought into the sliding surface when the ring rotates for lubrication.

It should be pointed out that the size of eccentricity should not be too large, especially for high pressure, eccentricity will cause uneven pressure on the end face and uneven wear. For high speed seals, it is not advisable to use moving ring as eccentric ring, otherwise the machine will vibrate due to the balance of centrifugal force.

2. Slotting the end face:

It is difficult for high-pressure and high-speed machines to maintain the liquid film between friction surfaces, which is often destroyed by friction heat generated by high pressure and high speed. In this case, it is very effective to adopt grooving to strengthen lubrication. Both the moving ring and the static ring can be slotted, which is usually made of wear-resistant materials. The moving ring and the stationary ring should not be slotted at the same time, because this will reduce the lubrication effect. In order to prevent dirt or wear debris from entering the friction surface as much as possible, and to seal the liquid flowing in the centrifugal force direction (outflow type), the groove should be opened on the static ring to avoid dirt from being introduced into the friction surface by centrifugal force. On the contrary, when the liquid flows against centrifugal force (inward flow), the groove should be opened on the moving ring, and centrifugal force is helpful to throw the dirt out of the groove.

The small grooves on the friction surface are rectangular, wedge-shaped, or other shapes. Groove should not be too much or too deep, otherwise leakage will increase.

3. Static pressure lubrication:

The so-called hydrostatic lubrication is to directly introduce the pressurized lubricating liquid into the friction surface for lubrication. The introduced lubricating liquid is supplied by a separate liquid source, such as a hydraulic pump. With this pressurized lubricating fluid, the fluid pressure in the machine is opposed. This form is usually called hydrostatic pressure seal.

Measures should be taken to establish gas film lubrication for mechanical seal of gas medium, such as adopting gas static pressure controlled film mechanical seal or solid lubrication, that is, using self-lubricating material as actuating ring or static ring. As long as conditions permit, the gas medium condition should be changed into liquid medium condition as much as possible, which is convenient for lubrication and sealing.

NEXT:9 Tips for choice seals rubber material?

Hot Products

-

View More

View More

-

View More

View More

Magnetic Abs OEM Bearing Seals China Manufacturer

-

View More

View More

Automobile Brake Disc Wheel Bearing Seals China Supplier

-

View More

View More

EPDM rubber o-ring seal different size factory China manufacturer

-

View More

View More

Automotive Oil Filter Rubber Check Valve

-

View More

View More

HNBR O Ring Seal OEM Manufacturer China

-

View More

View More

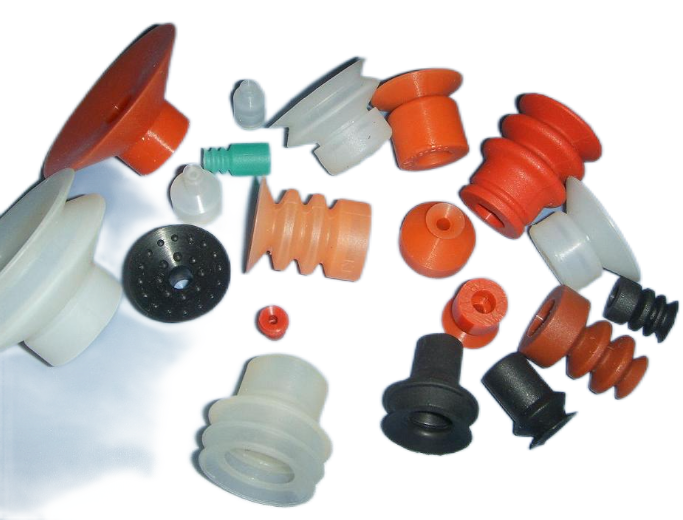

Rubber High Pressure Suction For Electronic Hand OEM China Factory

-

View More

View More

John Deere Tractor Cassette oil seal RWDR Manufacturer

-

View More

View More

High Pressure TCN Oil Seal for Excavator

-

View More

View More

Trailer Grease shaft rubber lip oil seal TB 11174

-

View More

View More

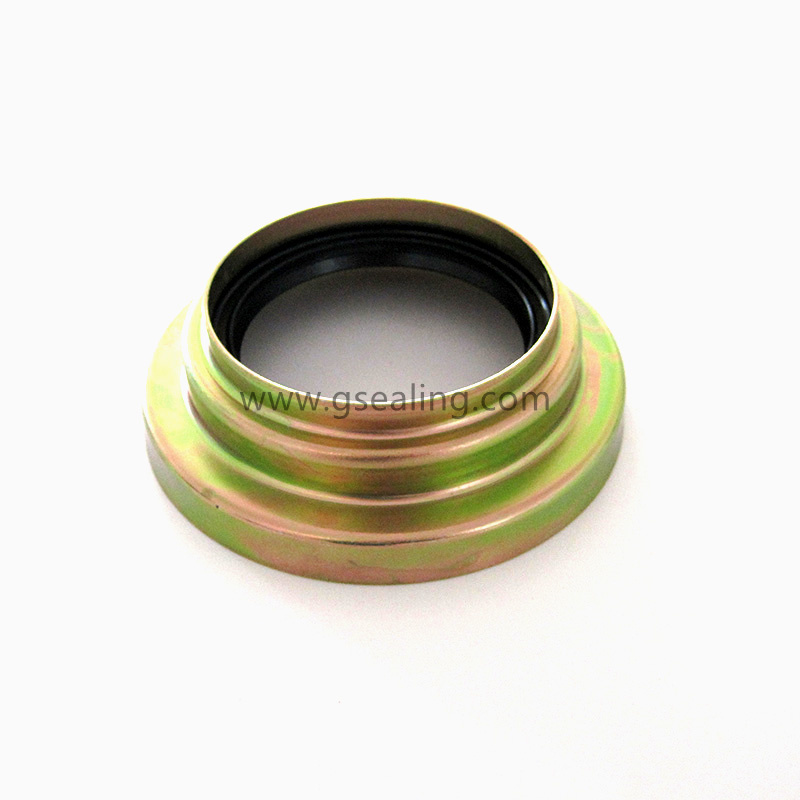

Ford New Holland Tractor Half Shaft Seal Retainer Assembly China Manufacturer

-

View More

View More

Irrigation Valley Valmont Gearbox Oil Seal China Supplier

-

View More

View More

High Quality Agriculture Machinery Rotation Oil Seal Kits

-

View More

View More

John Deer Grease Drive Shaft Oil Seal China Supplier

-

View More

View More

Tractor shaft combine oil seal